|

JOINT INTRODUCTION OF T-TYPE DUCTILE IRON PIPE T型接口球墨铸铁管接口介绍 |

|

T型接口又叫T型承插划入式柔性接口,是球墨铸铁管***常用的接口型式。使用历史60年,是 密封效果******的接口。

The T-type joint, also known as the T-type socket-spigot flexible joint, is the most common joint for ductile iron pipes. With a history of 60 years, it is the best joint for sealing.

T 型接口密封原理 Sealing principle of T-type joint

T型接口安装时,管子在插口外壁挤压,安放在承口内的橡胶圈,使其压缩变形,而产生一定的 接触压力,利用橡胶圈的自密封作用来保持接口的密封性。

When the T-type joint is installed, the pipe is squeezed on the outer wall of the spigot, the rubber ring placed in the socket is compressed and deformed to generate certain contact pressure, and the self-sealing action of the rubber ring is used to maintain the sealing property of the joint.

T 型接口特点 Characteristics of T-type joint

该接口具有结构简单。安装方便.密封性能好等特点,在窗口结构上考虑了密封圏和接口的偏转, 通过控制插口的安装深度,使得接头具有一定的抽象伸缩量,因此这种接口能适应一定的基础沉降, 同时可利用其偏转角度实现管线长距离的转向安装,接口。胶圏有硬胶和软胶两部分组成,硬胶对 管道接口有一定的支撑和对心作用。

The joint has the characteristics of simple structure, convenient installation, good sealing property and the like. The deflection of the sealing ring and the interface is considered in the window structure. By controlling the installation depth of the spigot, the interface has certain abstract expansion and contraction, so the interface can adapt to certain foundation settlement, and at the same time, the long-distance steering installation of the interface on the pipeline can be realized using its deflection angle. The rubber ring is composed of two parts: hard rubber and soft rubber, wherein the hard rubber has certain supporting and centering effect on the pipeline interface.

涉及领域 Fields involved

有/无压输水,饮用水.污水管线

地下地上铺设,且管道的铺设坡度不超过20% (地上铺设)或25% (地下铺设)

Water delivery with/without pressure, drinking water, sewage pipeline

Laying on and under the ground, the laying slope of the pipeline is not more than 20% (ground laying) or 25% (underground laying)

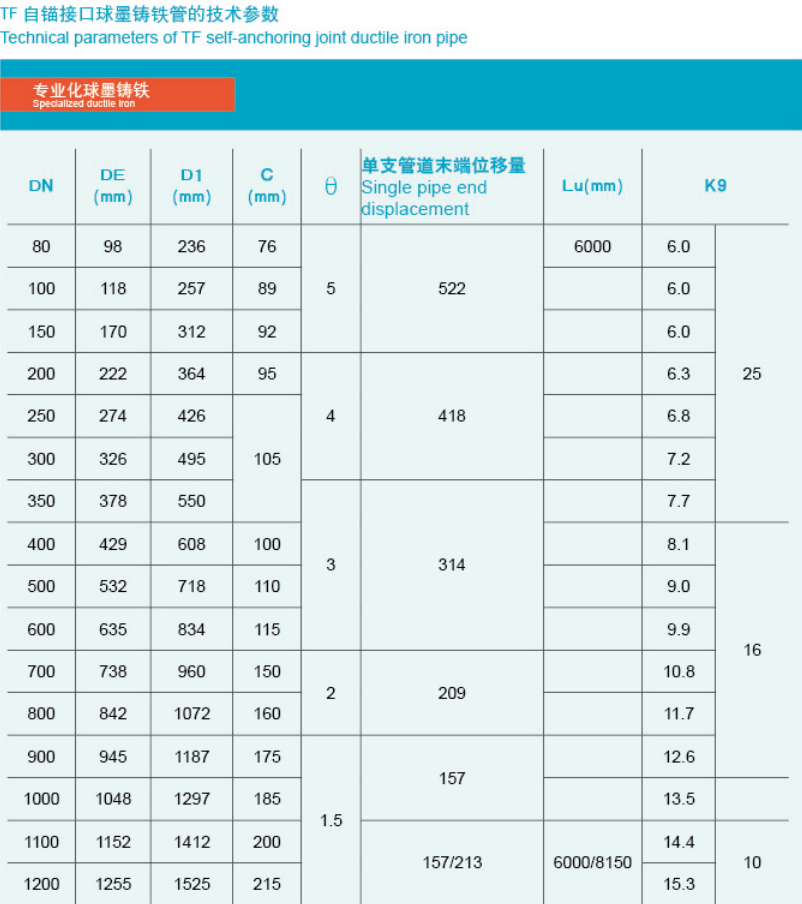

JOINT INTRODUCTION OF TF

SELF-ANCHORING JOINT

DUCTILE IRON PIPE

TF自锚管接口球墨铸铁管接口介绍

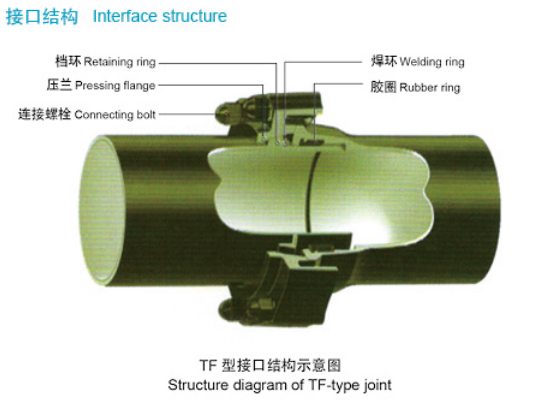

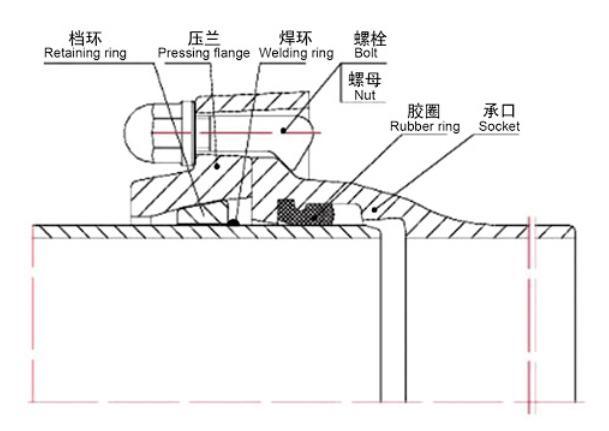

TF自锚接口采用了 T型接口的密封结构。相比T型接口,它増加了焊接在管子插口端的焊环、 活动开口挡环、特殊压兰以及连接螺栓以及附件,使接口具有较好的抗拔脱能力。挡环和压兰之间 可以滑动,使接口具有一定的轴向伸缩和偏转能力。

The TF self-anchoring joint uses the sealing structure of the T-type joint. Compared with the T-type joint, it adds a welding ring welded at the pipe spigot end, a movable opening retaining ring, a special pressing flange, a connecting bolt and accessories, so that the interface has better pull-out resistance. The retaining ring and the pressing flange can slide, so that the joint has certain axial expansion and deflection abilities.

TF自锚管推岀的必要性 Necessity ofTF self-anchoring pipe promotion

由于管线在安装时,经常会遇到地基的不均匀沉陷、转弯处无法安装支墩等的现实情况。所以, 解决接口的防拔脱问题就显得非常重要。从而开发了 TF型自锚式接口球墨铸铁管。

When a pipe is installed, it often encounters the actual situations that the foundation is not settled uniformly, piers cannot be installed at the turn, etc. So, it is very important to solve the problem of pull-out resistance of the interface. Thus, TF self-anchoring joint ductile iron pipes were developed.

TF 自锚式球墨铸铁管的工作原理 Working principle of TF self-anchoring ductile iron pipe

压力管线在拐弯、三通等处产生的轴向推力使接口处的承插口组件产生相对位移。插口端轴向 应力通过焊环、挡环、压兰、连接螺栓传递给承口,从而实现了轴向应力的传递,使接口具备防滑 脱能力。当形成约束连接一定长度的管道与周围土壤的摩擦力超过管道内部产生的轴向应力时.就 能保证管道的安全运行,从而避免了砌筑混凝土支墩。

The axial thrust generated by the pressure line at corners, tees, etc. causes relative displacement of the spigot assembly at the interface. The axial stress of the spigot end is transferred to the socket through the welding ring, the retaining ring, the pressing flange and the connecting bolt, thereby realizing the transfer of the axial stress and enabling the interface to have the anti-slip capability. When the friction between the pipe having the constrained length and the surrounding soil exceeds the axial stress generated inside the pipe, the safe operation of the pipe can be guaranteed, thereby avoiding the construction of concrete piers.

使用领域Applications

在下列情况下可通过铺设一定长度的自锚接口球虽铸铁管来防止管线接口滑脱:

1. 弯头、三通、异径管和堵头等处;

2. 当管线的铺设坡度超过20% (地上铺设)或25% (地下铺设)时;

3一设置混凝土支墩不经济时(如大口径高压管线等)或在某些特殊情况下,设置支墩措施不能 实施时,如:

(1) 施工场地过于狭窄,没有空间设置规范规定的十吨;

(2) 施工工期紧张等。

The pipeline interface can be prevented from slipping by laying a length of self-anchoring interface ductile iron pipe under the following situations:

1, at elbows, tees, reducers, plugs, etc.;

2, when the laying slope of the pipeline is more than 20% (ground laying) or 25% (underground laying);

3, when the setting of concrete piers is not economic (such as large-caliber high-pressure pipelines, etc.) or cannot be implemented in some special cases, for example:

(1) the construction site is too narrow, and there is no space to set ten tons as specified in the criteria;

(2) the construction period is short, etc.

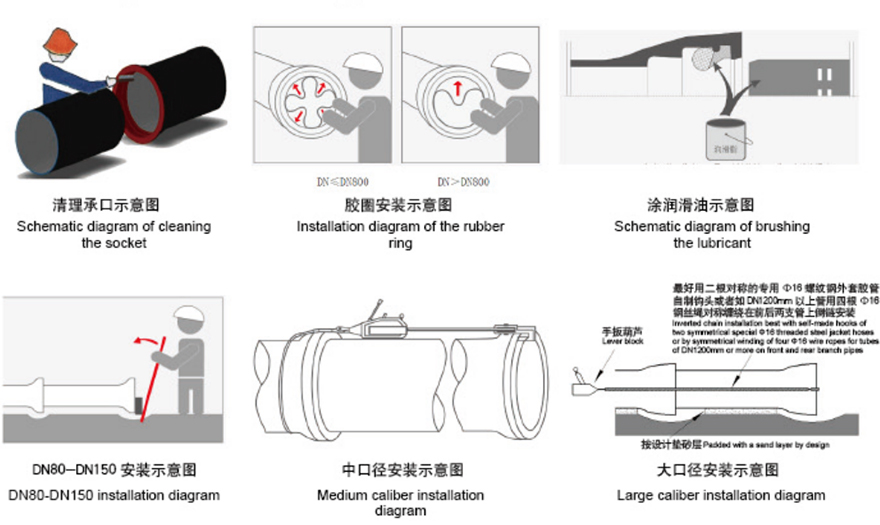

T型球墨铸铁管的安装 Installation of T-type ductile iron pipe

清理承口插口 —>清理胶圏 —>安装胶圏 —>下管(排管) —>在插口外表和胶圈上刷润滑剂 —>顶推管子使之插入承口 —>检査。

Clean the socket and spigot —> clean the rubber ring —>install the rubber ring —>detach the pipe (discharge the pipe) —>brush the lubricant on the outer surface of the spigot and the rubber ring —>push the pipe to insert into the socket —>check.

球墨铸铁给水管安装要点:Installation points of ductile iron water supply pipe:

■清理管口:将承口内的所有杂物******擦洗干净。

■清理胶圈、上胶圈:将胶圈上的粘着物清擦干净,把胶圈弯为“梅花形”或“8”字形装入承口槽内, 并用手沿整个胶圈按压一遍,或用橡皮锤砸实,确保胶圈各个部分不翘不扭,均匀地卡在槽内。

■在插口外表面和胶圏上涂刷润滑剂:将润滑剂均匀地涂刷在承口安装好的胶圈内表面、在插口外 表面涂刷润滑剂时要将插口线以外的插口部位全部刷匀。

■ Clean the socket: remove all debris from the socket.

■ Clean and install the rubber ring: clean the adhesive on the rubber ring, bend the rubber ring into a plum shape or 8 shape and install it into the socket, press the entire rubber ring once by hand or tamp it with a rubber mallet to ensure that each part of the rubber ring is not warped or twisted and is evenly caught in the groove.

■ Brush the lubricant to the outer surface of the spigot and the rubber ring: brush the lubricant evenly on the inner surface of the rubber ring installed on the socket, and brush the entire spigot outside the spigot line when brushing the outer surface of the spigot.

胶圈安装 Install the rubber ring

■球墨铸铁管在安装型橡胶圈前,先用钢丝刷清理承口内側胶圈球头座及凸像座槽沟,表 面应平整光滑,无任何机械杂质。然后在球头座处刷一层与胶圈不起反应的润滑剂(或肥皂剂)。

■往承口内安装型胶圈时,用右手将胶圏握成“凹”型,左手配合将胶圈硬凸缘牢固压入 定位沟槽内’定位后再依次将胶圈压平展.紧固于承口内。

■球墨铸铁管在安装型像胶圈时,为了便于安装’可以将胶圈两点握成“8”型.这样可 以从两侧将凸缘先压入定位槽内,防止凸缘弹岀定位沟槽。

■球墨铸铁管的型像胶圈安装完毕后,在胶圈内表面刷一层润滑剂薄膜以利于插口的推入。

■插口端头到插入深度标记这一段外皮清理后,也刷一层润滑剂,然后用合适的工具(撬棍、手 拉葫芦等),将插口保持同心地插入承口座,直到******条标记线消失为止。

■球墨铸铁管的型橡胶圈安装完毕后,应用特别的塞尺,沿四周控測一次间隙’以判断胶 圈位置是否正确无误。

■球墨铸铁管的型胶圈低于0摄氏度气温将变硬.因此安装管道时,应事先将胶圈贮存在 大于10摄氏度的室内。

■球墨铸铁管及胶圈在运输过程中.防止日晒、雨淋,严禁锐器刺扎及油物质侵袭。

■球墨铸铁管的胶圈应贮存于阴凉干燥处,勿扭折变形,防止损伤和污垢,避免阳光直接照晒。

Before the UT" type rubber ring is installed at the ductile iron pipe, clean the rubber ring ball seat inside the socket and the convex seat groove with a wire brush to ensure a smooth surface without any mechanical impurities. Then brush a layer of lubricant (or soap) that does not react with the rubber ring at the ball seat.

■ When the T type rubber ring is installed into the socket, hold the rubber ring into a "concave” shape with the right hand, press the hard flange of the rubber ring firmly into the positioning groove with the left hand, flatten the rubber ring after positioning, and fasten it in the socket.

■ When the T rubber ring is installed at the ductile iron pipe, in order to facilitate the installation, the rubber ring can be held in a shape at two points, so that the flange can be first pressed into the positioning groove from two sides to prevent the flange from popping up the positioning groove.

■ After the “T” rubber ring of the ductile iron pipe is installed, brush a layer of lubricant film on the inner surface of the rubber ring to facilitate the pushing of the spigot.

■ After the outer surface from the spigot end to the insertion depth mark is cleaned, also brush a layer of lubricant, then use an appropriate tool (a crowbar, a chain hoist, etc.) to insert the spigot concentrically into the socket seat till the first marking line disappears.

■ After the UT' rubber ring of the ductile iron pipe is installed, use a special feeler gauge to measure the clearance along four sides to judge whether the position of the rubber ring is correct.

■ The T rubber ring of the ductile iron pipe will become hard at the temperature of less than 0 c . Therefore, when a pipe is installed, the rubber ring should be stored in a room of more than 10'c in advance.

■ Ductile iron pipes and rubber rings are protected from sunlight and rain during transportation, and sharp puncturing and oil attack are prohibited.

■ The rubber rings of the ductile iron pipes should be stored in a cool and dry place, should not be twisted